SAFEGUARD YOUR MAINTENANCE TEAM & PRODUCTION

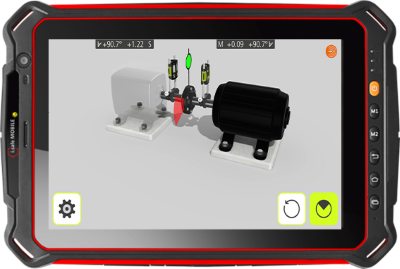

Fixturlaser EXO

A Smart Alignment System Certified for Work in Hazardous Areas

Our core values, GuideU and Alignment Intelligence, have led to the development of several first industry functions, where True Live and VertiZontal Moves™ are unique on the market for laser-based shaft alignment tools. They bring ease of use to our end users, which above all facilitates easy precision shaft alignment, on-the-job time saving, improved reliability, and more importantly, money savings.

With the FIXTURLASER EXO, you get all this in an intrinsically safe shaft alignment package.

Easy-to-Use Shaft Alignment in Hazardous Areas

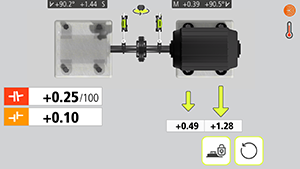

TRUE LIVE

You Always Know Your Machine’s Position with the FIXTURLASER EXO

The True Live feature will deliver live measurement values showing the machine’s exact position. Did you interrupt the laser beam? Or move the machine’s position out of the detector range? Not a problem, our smart sensors will resume with an updated machine position and always deliver live values to you.

Industry-leading EX certified smart sensors

- Integrated Bluetooth for wireless communication between the display unit and smart sensors

- 30 mm digital sensor detector + line laser eliminates rough alignment, which results in a short setup time

- Built-in dual inclinometers to detect backlash and obtain angular values during measurement in horizontal alignment

- Thinnest smart sensors on the market

- Premounted fixtures give a short setup time

- Instant battery check – in both on and off mode

- II 3G Ex ic op isIIC T4 Gc

EX certified tablet with an app and icon-based user interface

- Icon-based and color-coded user interface a language-free user interface

- True live values during adjustment

- Animated arrows indicating adjustment orientation and misalignment magnitude

- Integrated Bluetooth for wireless communication between the display unit and smart sensors

- ATEX/IECEx Zone 2 certified including ruggedized IP68 tablet device

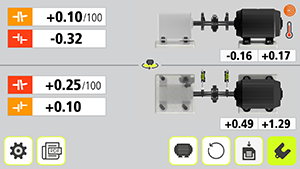

GuideU

Our Graphical User Interface, Your Alignment Guide

Our patented icon- and app-based, and color-coded user interface, GuideU, makes it easy to measure, align, and document each job. In order to minimize the risk of operator errors, we developed an adaptive user interface for the FIXTURLASER EXO system. It guides the user throughout the job in logical and easy-to-follow steps. It will deliver measurement and correction values based on what the system finds during the alignment process.

This eliminates confusion for less-experienced users and provides ease of access throughout a measurement with the FIXTURLASER EXO system. To add to the enhanced user experience, we have given the interface a game-like 3D graphic look facilitating the unmistakable interpretation of any misalignment error.

Our icon-driven, language-free alignment systems produce measurement reports easily understood by all users, regardless of their language.

Vertizontal Moves™

Measure Once, Move in Two Directions

The VertiZontal Moves™ feature displays exactly how much a misaligned machine needs to be adjusted and in which direction, by adding or removing shims to the machine’s feet. No more re-measuring between the vertical and the horizontal phases to correct the horizontal misalignment.

This industry-first function saves time and ensures accuracy the first time around. Time savings mean cost savings for the maintenance department, the production department. In short, savings for the entire company.

| Weight including all standard parts | 6,6 kg (14,6 lbs) |

| Storage temp | -20 to 70°C (-4 to 158°F) |

| Long term storage temp | Room temp. 18 to 28°C (64 to 82°F) |

Find The Right Device

Then please get in touch and we'll be glad to help.